Program 2. Mineralogy

Understanding ores and mineral chemistry.

Many critical mineral resources do not form high grade ore deposits, but occur in trace amounts in other ores. And several critical metals, such as indium, cobalt and germanium, rarely reach economic concentrations of their own. Comprehensive knowledge of their mineralogy and mineral chemistry is essential if we are to successfully develop the industry and identify opportunities for the recovery of critical minerals as economic by-products.

The Mineralogy Program uses advanced microanalytical and spectroscopic techniques and facilities to boost understanding of critical mineral ores and mineral chemistry.

-

Research questions

- Can we refine exploration methodologies and optimise mineral processing and recovery with improved knowledge of mineralogy and mineral chemistry?

- How can critical minerals be efficiently extracted, as primary or by-product commodities?

- How can we control associated environmental impacts, including the treatment of radionuclides and hazardous metals (such as arsenic or mercury)?

-

Research goals

- Characterise and understand the controls on metal distribution in ore minerals, including potentially hazardous radionuclides

- Understand the solubility and stability of critical minerals in geological environments

- Identify new, extractable resources within existing ores and wastes

- Develop practical applications for industry, such as improved exploration tools, rapid ore characterisation and metal deportment

- Develop sensors for exploration drilling, core logging and rapid ore screening.

- Develop low-energy methodologies to concentrate and recover critical minerals.

-

Centre expertise

- Complex mineralogy and deposit formation in ores, concentrates, tailings and smelter slags across the critical mineral spectrum

- Combining knowledge of geology, mineralogy, geochemistry and mineral processing

- Geometallurgy

- Critical mineral deposits

- Copper, gold and uranium deposits that contain critical minerals as byproducts

- Opportunities for refining, value addition and end-product manufacture in Australia

-

Example projects

Trace elements in iron oxides

The goal of industry project ‘Trace elements in iron oxides: deportment, distribution and application in ore genesis, geochronology, exploration and mineral processing’ (called the FOX Project) is to understand trace elements in iron ores. This is critical for metallurgical studies and ore processing, and for designing novel exploration models for new or satellite prospects. The project looks at both IOCG and BIF-derived ores.

Partners: BHP, SA Government, British Geological Survey, Curtin University.

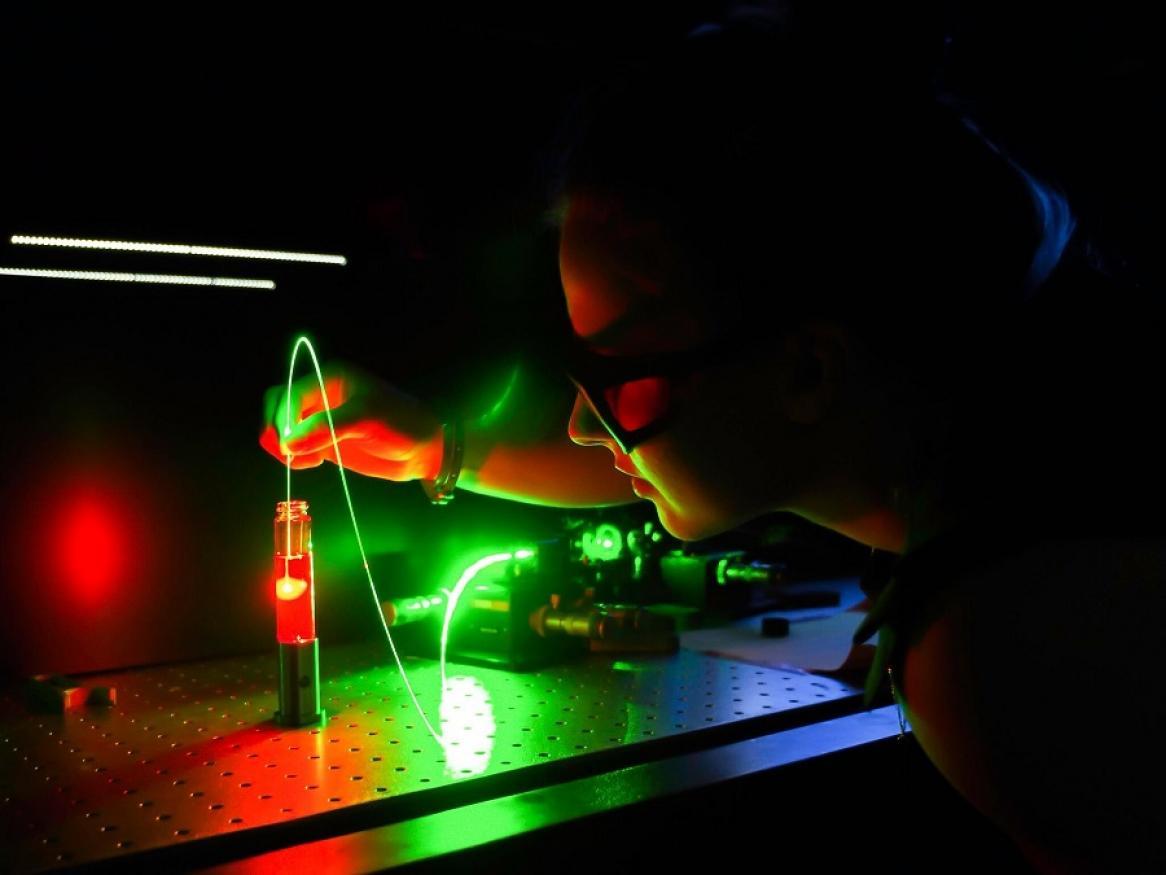

New class of sensor for minerals assessment and processing

Mineral and material identification in real-time using novel fluorescence techniques is a globally-leading emerging strength at the centre. Our expertise began in a program at CRC ORE (Optimising Resource Extraction) for ‘selective mining’ research, which was then expanded with funding from the Defence ‘Next Generation Technology Fund’ Grand Challenge, Counter-Improvised Explosives (Project CIT 186) to investigate stand-off sensing of explosives and IEDs. REEs and critical minerals are being discovered to have unique and exploitable ‘novel fluorescence’ signatures, opening the way for a new class of sensor for resource assessment and mineral processing control.

Partner: CRC ORE

-

Key contacts