Industry collaboration delivers improved face shields

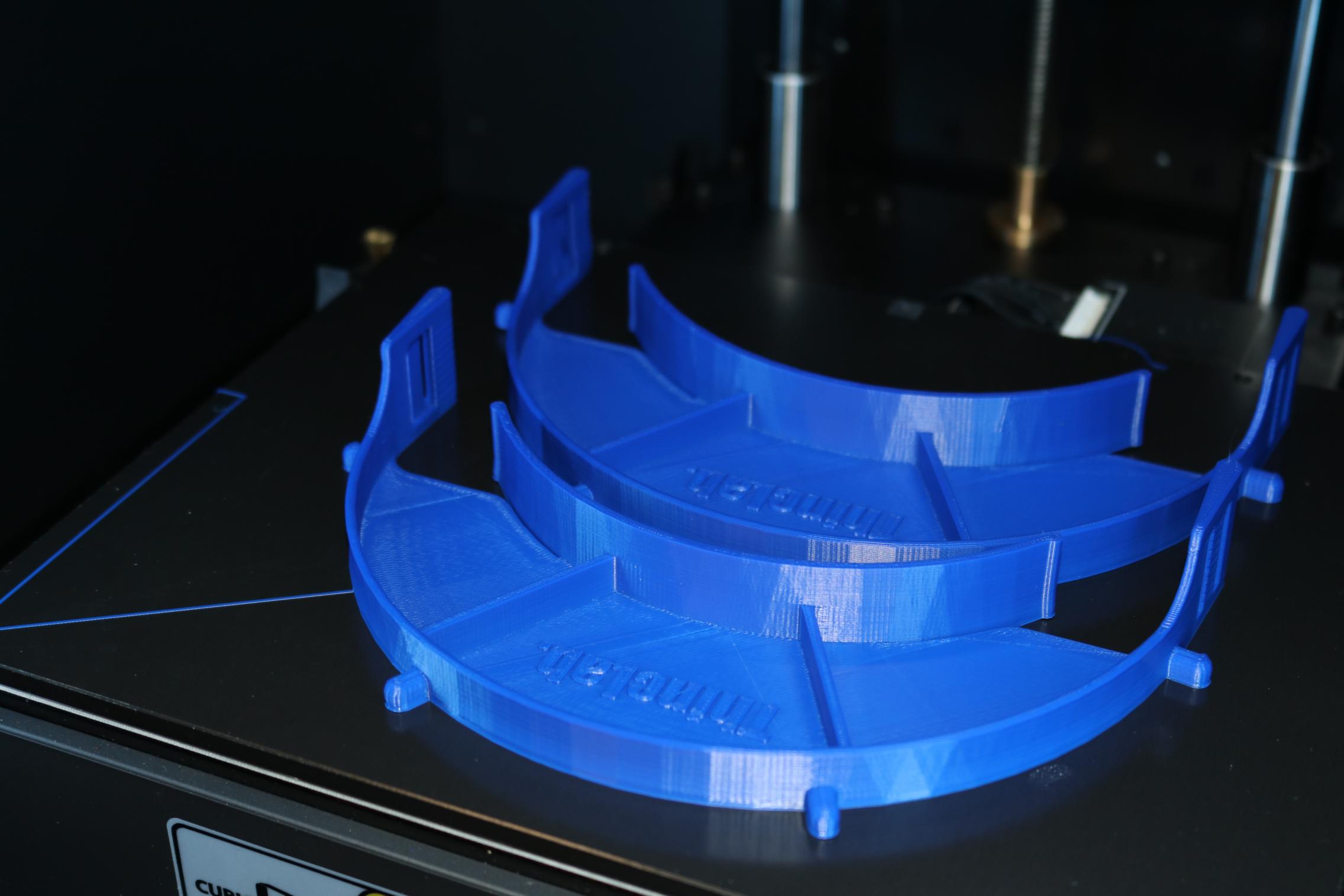

Face shield 3D printed at ThincLab Waite

The University of Adelaide’s ThincLab business incubator has teamed up with Clinpath Pathology to supply them with improved face shields.

The new face shields have been developed in response to calls from the medical profession for protective equipment that does not fog, can be worn over specialised glasses, and which can be quickly and cheaply replaced by the user when required.

Morgan Hunter, TechLab Manager, University of Adelaide ThincLab says, “A number of different organisations have asked to test face shields in the marketplace which they could produce to meet the need in South Australia. Many of these designs come from the US or Europe. The main issue with all of them was the screen had to be custom-made which increased the cost.”

Clinpath, which provides laboratory services to general practitioners, specialists, private hospitals, and aged care facilities in Adelaide, needed to purchase appropriate PPE for their staff. Equipment available from overseas proved more costly so they turned to local suppliers and supported the broader community in the process.

“The face masks, which are being produced at ThincLab at the University’s Waite campus, are a perfect example of locally produced solution for unprecedented times.”Zrinka Tokic, Director of ThincLab

Brooke Kenny, Clinpath Pathology’s Pre Analytics Manager says, “Our staff at Clinpath have a focus of keeping patients safe, encouraging them to maintain their health and helping them choose the most appropriate way for them to have their pathology test completed. In this climate, the company ethos has been to remain flexible and approachable and support whenever we can.”

Face shields are better than medical masks as they are more durable, can be reused indefinitely, can be easily cleaned, are more comfortable to wear, prevent the wearer from touching their face and do not have to be removed to communicate.

The face shields supplied by ThincLab, which are 3D printed, feature a convenient elasticated strap which is cheaper and easier to make than competitors’ products and which makes it adjustable for any head size and pressure. ThincLab then incorporated a solid top shield in the frame, which prevents pathogens from entering from the top. These features made the mask more adaptable and replaceable than competitors’ products.

Zrinka Tokic, Director of ThincLab says, “Even in these times of isolation, ThincLab is still actively collaborating with industry to develop innovative solutions to problems we are facing. We are proud to be able to offer support and services to start ups and industry through this challenging time as it is proving to be a catalyst for insightful and agile solutions.

“The face masks, which are being produced at ThincLab at the University’s Waite campus, are a perfect example of locally produced solution for unprecedented times.”

Crispin Savage

Senior Media and Communications Officer

Mobile: 0481 912 465

Email: crispin.savage@adelaide.edu.au