OptoFab Adelaide

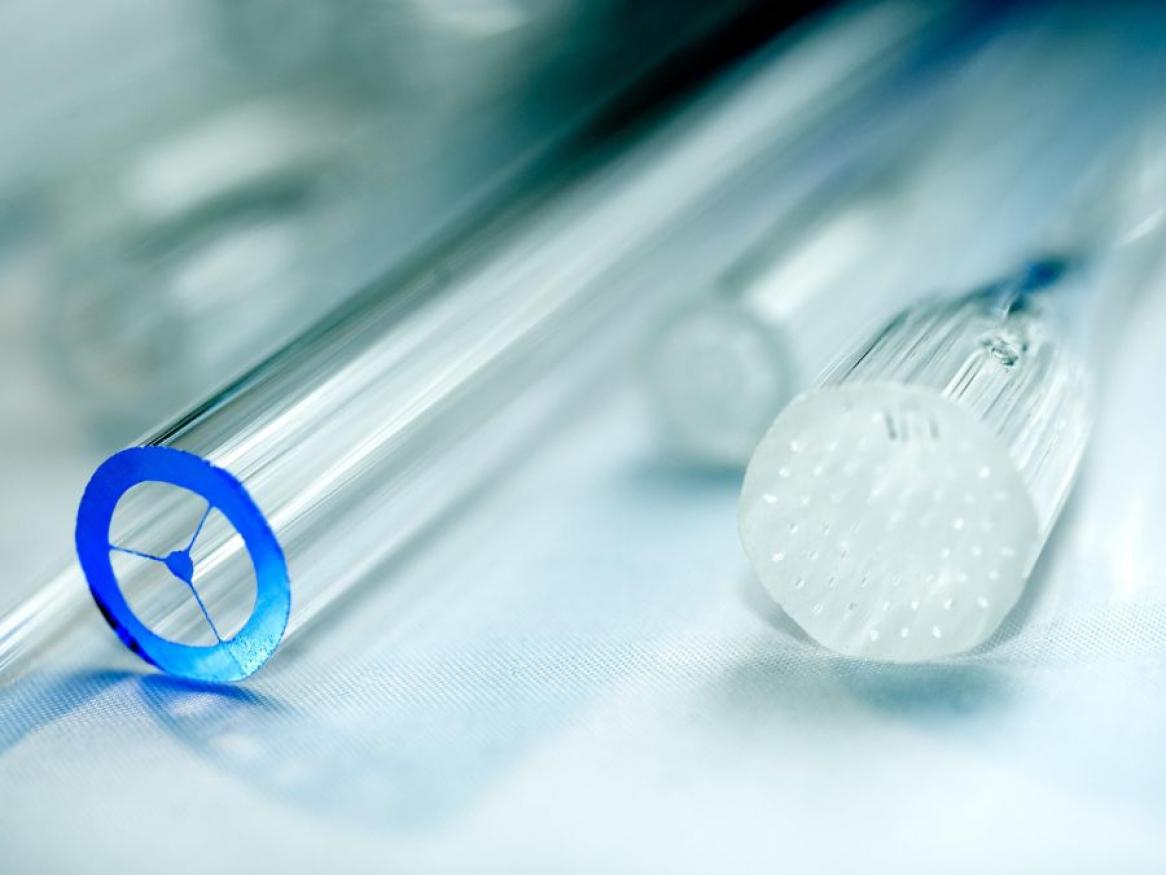

Optofab Adelaide, located in The Braggs building, offers fabrication services for custom optical glass with unique properties, extrusion capabilities for specialised preforms for optical fibres, and fibre drawing capabilities for glass, silica, and polymers, including microstructured fibres.

Adelaide has a rare combination of glass science and fibre fabrication research facilities and expertise, which has enabled the realisation of fibres with unique and novel properties. Optofab Adelaide also provides complex and precise machining services. Its additive and subtractive manufacturing capabilities allow the creation of glass, polymer and high-strength metal parts with complex shapes and geometries tailored to specific performance requirements.

Australian National Fabrication Facility (ANFF)

Established under the National Collaborative Research Infrastructure Strategy, the Australian National Fabrication Facility (ANFF) links 8 university-based nodes to provide researchers and industry with access to state-of-the-art fabrication facilities.

The capability provided by ANFF enables users to process hard materials (metals, composites and ceramics) and soft materials (polymers and polymer-biological moieties) and transform these into structures that have applications in sensors, medical devices, nanophotonics and nanoelectronics.

-

The nodes

The nodes, which are located across Australia, draw on existing infrastructure and expertise.

Each offers a specific area of expertise including advanced materials, nanoelectronics and photonics and bio nano applications.

Our commitment to providing a world-class user facility is underpinned by the sharing of best practice in service provision across the nodes.

-

The ANFF difference

Of course, opening the doors to world-class infrastructure is only the first step. Without dedicated staff to support access, your potential breakthrough research remains just an idea.

Each ANFF node has experts on hand to assist researchers, experienced in meeting user requirements and maintaining leading-edge instrumentation. In fact, over 60 technical staff positions are funded through the program.

Researchers are able to either work at the node under expert guidance, or to contract for specialised products to be fabricated at a reasonable cost.

-

Optofab node of ANFF

Optofab offers specialist facilities and dedicated staff that are on hand to provide services and technical support to users in microprocessing, microfabrication and characterisation of fibre, planar and bulk materials which include silica, metals, ceramics, silicon, polymers and crystals.

Optofab services have proved beneficial for applications in telecoms, biotechnology, biomedicine, microelectronics, optical sensing, industrial processing, defence and security.

The Node consists of centres at Macquarie University (headquarters), University of Technology Sydney, the University of Adelaide, the Australian National University, and the University of Sydney.

-

Acknowledgement

IPAS glass, fibre and surface characterisation facilities are an integral part of the Optofab node of the Australian National Fabrication Facility, a company established under the National Collaborative Research Infrastructure Strategy to provide nano and micro fabrication facilities for Australia's researchers and companies.

All users of ANFF equipment and products made using ANFF capabilities are asked to acknowledge ANFF in papers as follows "This work was performed in part at the OptoFab node of the Australian National Fabrication Facility utilizing Commonwealth and SA State Government funding."