Sustainable Energy, Mining & Resources

-

Addressing water security down under

Australia faces a challenge in securing its water supply amidst climate change and prolonged droughts. About 30% of the country's water, used for human consumption, stock watering, irrigation, and mining, is sourced from groundwater. With surface water increasingly unreliable, ensuring sustainable groundwater usage is crucial.

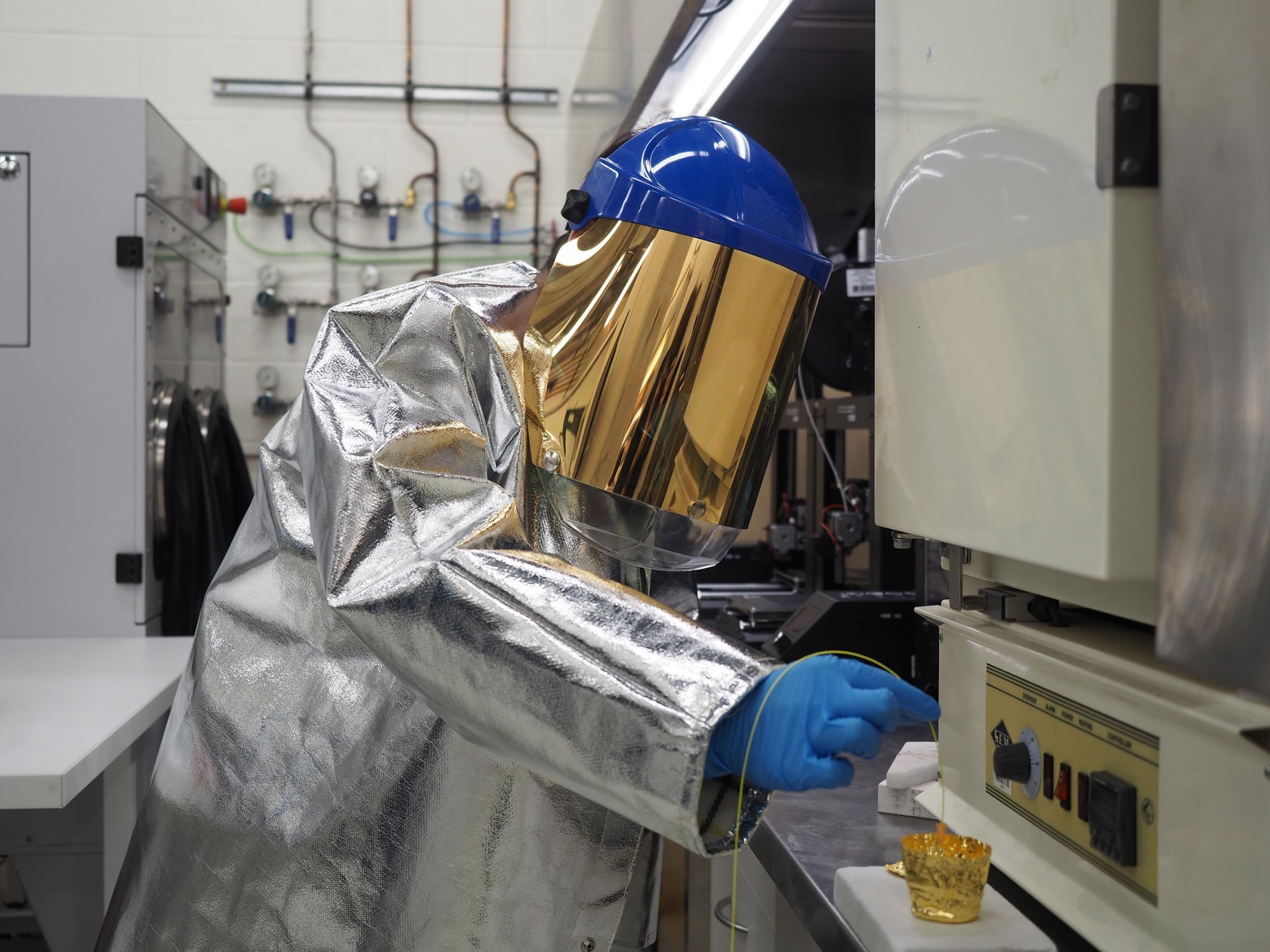

The Atom Trap Trace Analysis (ATTA) team at the University of Adelaide addresses this challenge. The ATTA facility, the first of its kind in the Southern Hemisphere, has teamed up with CSIRO's Noble Gas Facility in Adelaide, providing one of the most comprehensive noble gas analysis capabilities globally.

Under Dr. Rohan Glover's leadership, the team employs quantum technology to measure ultra-low concentrations of radioactive noble gases in groundwater, enabling researchers to determine water sources and recharge rates.

Noble gases act as reliable tracers as they do not easily mix or react with other substances. Their ability to dissolve in water and remain unchanged during geological processes makes them reliable sources of important information. By examining their concentrations and compositions in groundwater, researchers can learn about the water's age, where it came from, and even how different underground water systems are connected. This improves our understanding of the sustainable use of groundwater resources in arid and semi-arid regions, aids in the management of coastal groundwater systems, and informs on the migration of pollutants in shallow groundwater aquifers.

Beyond addressing Australia's water challenges, the extensive study of our groundwater informs on our changing climate, and Australia, being strongly affected, provides valuable climate archives in its groundwater. This state-of-the-art technology also holds promise for investigating the global climate history through Antarctica’s valuable ice, contributing to a global understanding of environmental change.

-

Detecting underground water leaks with black telecom optic fibres

In Australia, where the weather can be unpredictable and droughts are common, water resources are scarce and every drop counts. Monitoring underground water pipes to manage leaks is crucial, but it comes at a cost.

Over the last decade, water utilities have invested heavily in discrete Internet of Things (IoT) acoustic loggers attached to pipes to monitor acoustic noise generated by leaks in their water networks. With a typical spacing of 100 meters between sensors, it requires big investments. This system requires a dedicated team to conduct field investigations at night, maintain the sensors, and replace batteries.

But what if photonics offered a simpler and more affordable solution? In addition to water pipes, our underground infrastructure is filled with telecommunication fibre optic cables.

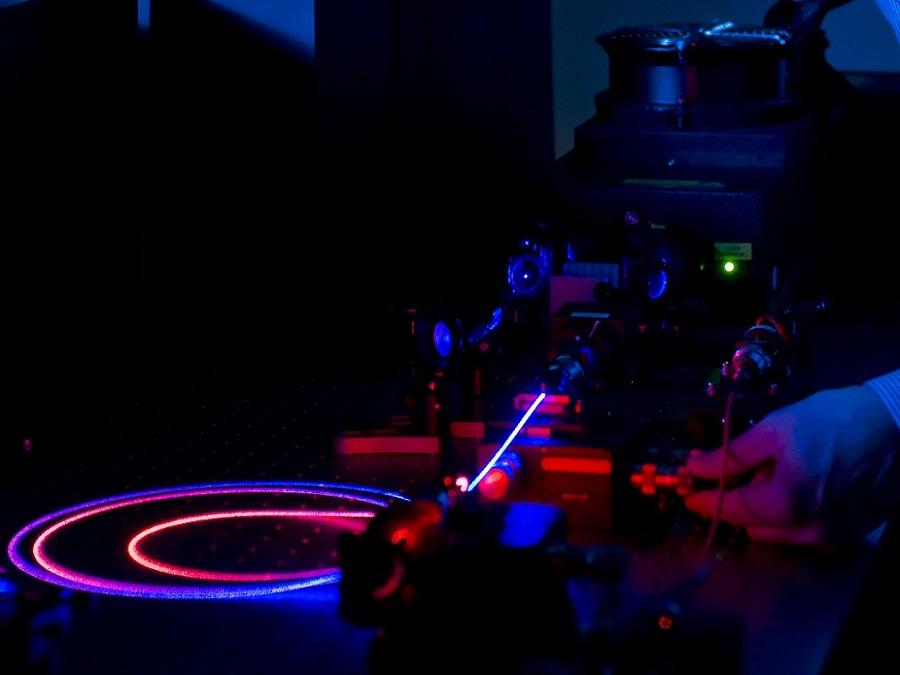

Dr Wei Zeng's ARC Discovery Early Career Researcher Award enables him to explore the possibilities of using advanced optical fibre sensing techniques for leak detection in water networks. His DECRA project uses the Distributed Acoustic Sensing (DAS) technique to transform hair-thin glass optical fibres into thousands of individual sensors to detect leak noise. More importantly, DAS can use “dark fibres”, which are the unused existing telecommunication fibre optic cables prevalent in modern cities.

The acoustic wave generated at the cracks/leaks transmits to the fibre through the soil between the pipe and the optical fibre. Unlike traditional sensors that rely on separate measurements at distinct points in time, DAS enables continuous, real-time measurements along the entire length of a fibre optic cable.

Once Wei has uncovered how leak noise generates, transmits, radiates, and eventually reaches the optical fibre, intelligent data analytic approaches will be developed to localize leaks and distinguish crack noise from environmental noise.

In Australia, 250,000 km of buried dark fibres offer a huge potential for monitoring underground water assets. Leaks waste water and strain management efforts, affecting both urban and rural areas. Aging infrastructure worsens the problem as older pipes are more prone to leaks. Addressing these leaks is crucial for conserving water and ensuring reliable supply.

By converting some of these dark fibres into sensors, we can save tens of millions of dollars compared to current systems. This new approach offers a cost-effective solution, potentially revolutionising smart water networks (SWNs) and advancing water asset monitoring technology.

-

Gold and silver for environmentally safe and colourful glass

Toxic heavy metals like lead and cadmium are often used to create bright colours in glass, but they can be harmful to both the environment and people’s health when present in high concentrations. These metals can leach out of glass fragments, especially when exposed to conditions similar to rain in a landfill, potentially making them hazardous.

The foundation for a safer alternative began around 2016 when Dr Yunle Wei, then a PhD student, and Jiangbo Zhao (Tim), a researcher in Professor Heike Ebendorff-Heidepriem's Photonic Materials & Optical Fibres Research Group, discovered a method using nanoparticles in tellurite glass, a concept they initially explored in a significant research paper. Over the years, they extended this approach to other glass systems, eliminating the need for toxic metals.In 2020, they co-founded EZY-GLAS Technology, a spin-off from the Institute for Photonics and Advanced Sensing (IPAS) at the University of Adelaide, to bring this eco-friendly, patent-protected technology to market.

By controlling the composition, size, and distribution of the nanoparticles, they can produce a wide range of beautiful, warm colours in glass without using harmful materials.Now, their focus is to turn their eco-friendly, patent-protected glass technology into a key building block for a more colourful and sustainable future. By making the glass industry safer and more environmentally friendly, EZY-GLAS is unlocking the potential of vibrant, non-toxic glass for everything from art to packaging.

-

High temperature sensor

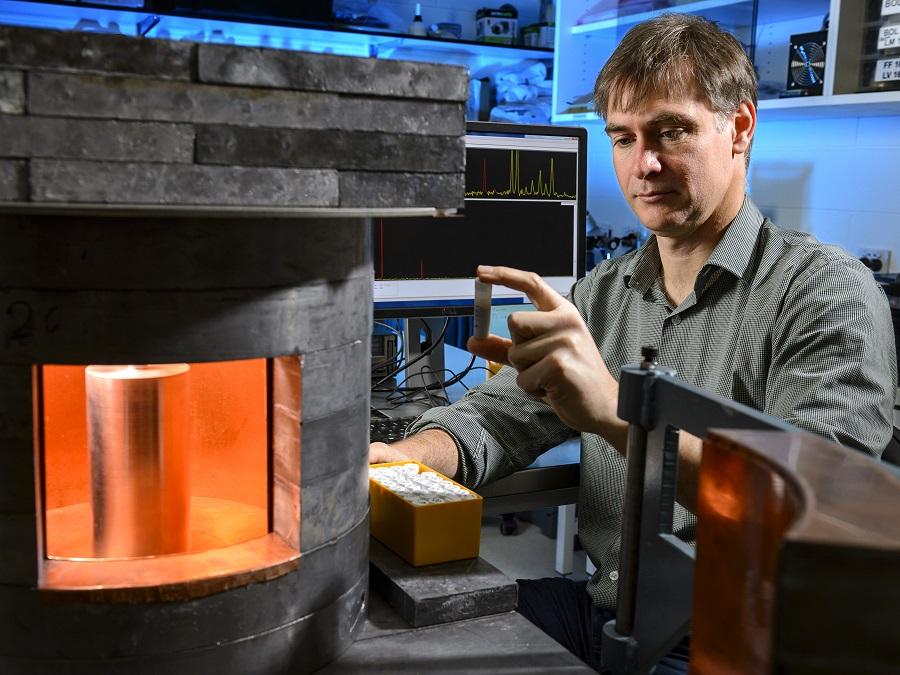

The measurement of temperature within high temperature furnaces poses significant challenges, since sensors are exposed to high and varying temperatures and often highly corrosive environments. Accurate temperature sensing inside a furnace during a full cycle will allow a reduction of overall energy use resulting in lower operating costs and greenhouse gas emissions.

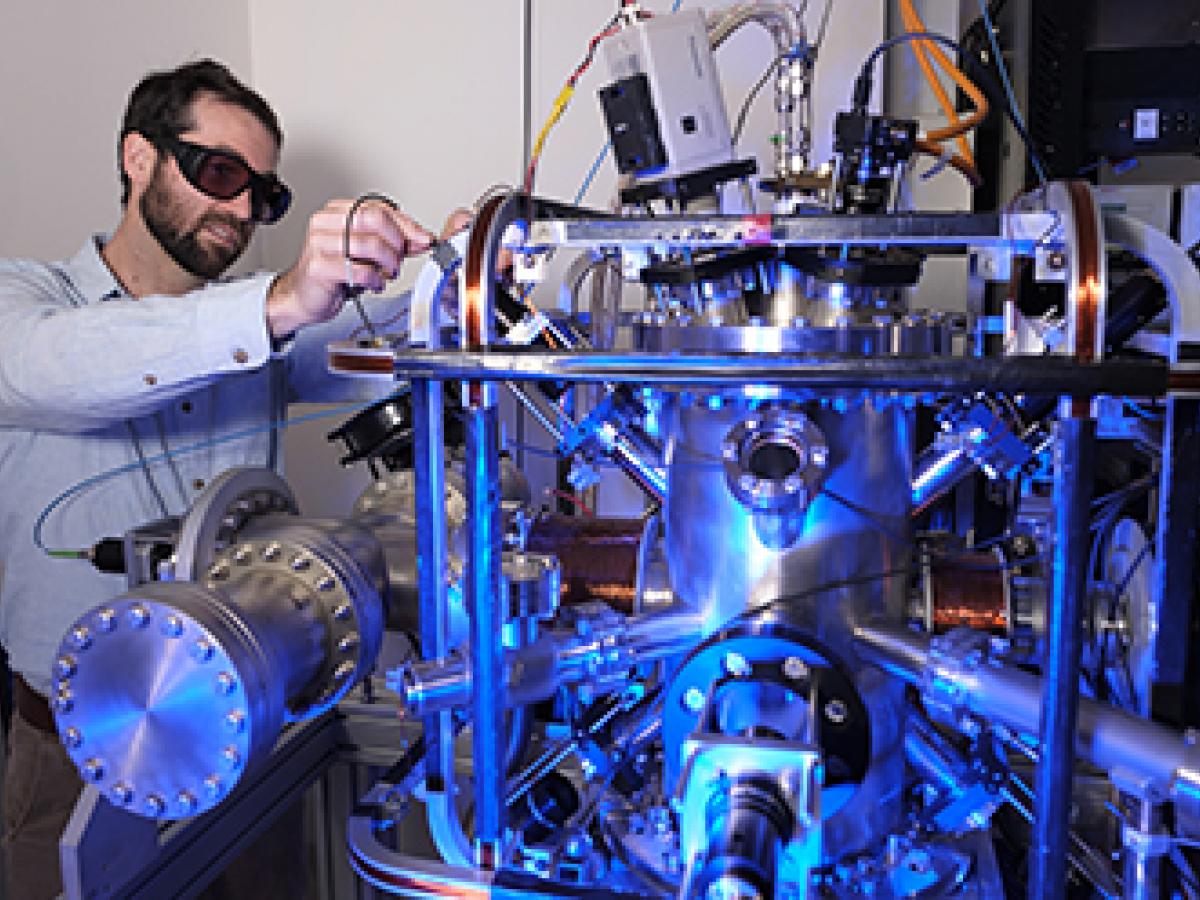

IPAS researchers have developed a high temperature sensor based on optical fibre technology that offers numerous advantages for measuring high temperatures: multipoint sensing, immunity to electromagnetic interference, corrosion resistance, small size, and the ability to sense in difficult locations. The sensor, based on fibre Bragg gratings within microstructured optical fibres, overcomes a key limitation of traditional fibre Bragg gratings, which do not work above 250°C. The patented sensors are made from pure silica microstructured optical fibre, which is fabricated at the University of Adelaide. We then modify these fibres with a femtosecond laser machining technique to produce the Bragg grating. As the thermometers are made of a single material that has been physically modified, they will operate successfully up to 1300°C.

The sensor has been developed in partnership with a 100-year-old South Australian engineering company, SJ Cheesman, located next to the Nyrstar multi-metals recovery plant in Port Pirie. SJ Cheesman, with their vast experience in the smelter industry identified a number of critical locations that would greatly benefit from this newly developed optical fibre temperature sensor technology. An initial program of work was carried out via a South Australian Government co-sponsored pilot study (Photonics Catalyst Grant), which allowed the sensors to be successfully developed and demonstrated within the smelter. An ARC linkage project followed, allowing further development of this critical technology. Incorporating the sensor into the zinc smelter enabled Nyrstar to understand the temperature of this critical operation for the first time in its 50 years of operation. This will inform future best practices in terms of energy consumption with direct potential economic and environmental impacts.

In 2017, giant industrial engineering and manufacturing company, Mitsubishi Heavy Industries, has signed a series of collaborative research contracts for IPAS to develop unique optical fibre based ultra-high, multipoint temperature sensors that will enhance the efficiency of their power generation systems. Mitsubishi came to Adelaide looking for global research partners and decided the Institute’s ultra-high temperature optical fibre sensors would provide a unique opportunity to better understand and improve their world leading power generation systems.

This new collaboration represents international recognition for the quality of IPAS’ research and development, and the difference these emerging disruptive technologies like photonics can make to businesses’ bottom lines. Temperature readings can help other companies improve energy efficiency, reduced emissions, and improvement in the design and lifespan of components, resulting in an overall enhanced competitiveness.

-

IPAS Node of the ARC Copper-Uranium Transformation Research Hub

The Hub, led by the Institute for Mineral and Energy Resources at the University of Adelaide, is enhancing the value of Australian copper resources by developing and testing new, cost-effective ways to remove nontarget metals from copper ores in South Australia and internationally; in partnership with researchers from the University of Queensland, Monash University, Flinders University, BHP, OZ Minerals, Defence Science and Technology Group and the Department of State Development.

IPAS member Prof David Ottaway is leading the Hub node dedicated to ‘Analysing the Rocks’, aiming to develop new scanning technologies to locate and quantify nontarget metals, including in real-time.

The IPAS team is developing solid state and liquid based radiation sensors for detecting natural radiation fields in copper ore. Within solid state sensing the group has created a revolutionary process to spatially locate alpha producing minerals to microscale resolution. This process will help quantify and understand mineral distribution within the ore. Liquid sensing utilises optical fibres to detect extremely low concentrations of non-target metals in real time at the mine site. Real time liquid sensing allows for rapid processing turnaround that can support a constantly operating mineral processing plant.

The Cu-U Hub has also leveraged over $1 million of additional funding to establish a Radiation Sensing Capability to evaluate mineral processing ore samples at different stages within the plant. The University of Adelaide based capability resides in the Braggs building.

-

High-Resolution Pipeline Condition Assessment Using Hydraulic Transients

Prof Martin Lambert's project, funded under a $499,000 ARC Discovery Project, aims to develop urgently needed non-invasive methods to assess the fine detail of a pipe’s condition and allow ‘just in time’ predictive repair. Water distribution networks are society’s most important infrastructure asset. They consist of buried pipes that are often old and deteriorating, and maintenance overhead exceeds $1 Billion per year in Australia alone.

The project will develop cost-effective powerful tools to identify faults, such as pipe wall corrosion and blockages, while allowing operational continuity. The expected outcome is high-resolution images of wall condition of pipes using high-frequency pressure transients and sophisticated fibre optic sensor arrays.

-

Next generation laser-based mineralogy sensing technology

IPAS researchers received $1,300,000 from the CRC ORE towards developing a new, laser-based technology for detecting and quantifying mineral species in real-time for coarse particles.

The project is led by Professors Nigel Spooner and David Ottaway.

The proposed technology is expected to be less sensitive to the known limitations of existing techniques such as laser-induced breakdown spectroscopy (LIBS) and laserinduced fluorescence (LIF).